NEW DELHI: The Union Cabinet on Wednesday approved the much-awaited incentive scheme to boost the manufacturing of semiconductors in the country.

Following the cabinet meeting – chaired by Prime Minister Narendra Modi – Union Ministers Anurag Thakur and Ashwini Vaishnav announced a Rs 76,000-crore Production Link Incentive (PLI) scheme for semiconductor and display board production in India.

“The government has decided to set up a complete ecosystem for semiconductors in the country. This will include design, manufacturing, packaging, testing,” Vaishnav said.

“This will strengthen India’s journey towards self-reliant India,” he said.

The Rs 76,000 crore plan will be spread over 6 years.

The Center plans to set up 20 semiconductor units in the country in the next two years.

Semiconductors and their uses

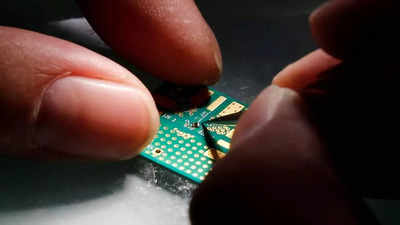

Semiconductors are silicon chips that fulfill control and memory functions in products ranging from automobiles, computers and cellphones to various other electronic items.

The use of semiconductors in the auto industry increased globally in recent times with technological advancements and new models coming with more and more electronic features such as Bluetooth connectivity and driver-assistance, navigation and hybrid-electric systems in addition to the engine control unit. Is.

What is the government planning to do

The government has arranged an attractive incentive support for companies engaged in silicon semiconductor fabs, display fabs, compound semiconductors, silicon photonics, sensor fabs, semiconductor packaging and semiconductor design.

It also works with State Governments on hi-tech clusters with necessary infrastructure in terms of land, semiconductor grade water, power, logistics and research ecosystem for approving applications for setting up at least 2 greenfield semiconductor fabs and 2 display fabs. will work together. Country.

Ministry of Electronics and IT will take necessary steps for modernization and commercialization of Semi-conductor Laboratory (SCL).

The IT ministry will explore the possibility of SCL’s joint venture with a commercial fab partner for modernization of the brownfield fab facility.

“The scheme for setting up of Compound Semiconductors/Silicon Photonics/Sensor Fab and Semiconductor ATMP/OSAT facilities in India will provide financial assistance of 30 per cent of the capital expenditure to the sanctioned units,” an official release said.

Under this scheme, at least 15 such compound semiconductors and semiconductor packaging units are expected to be set up with the support of the government.

A Design-Linked Incentive (DLI) scheme will offer incentives of up to 50 per cent of eligible expenditure on net sales and 6-4 per cent linked to product deployment for 5 years.

To drive long-term strategies to develop a sustainable semiconductor and display ecosystem, a special and independent ‘India Semiconductor Mission (ISM)’ will also be set up.

The mission will be led by global experts in the semiconductor and display industry and will act as the nodal agency for efficient and smooth implementation of plans on the semiconductors and display ecosystem.

Relief for key sectors

The decision comes as a big relief, especially at a time when industries across sectors are facing massive production cuts due to global chip shortage.

Amid a sharp jump in demand, businesses globally are grappling with the pressure of acute semiconductor shortages.

This resulted in long waiting periods across multiple consumer product categories such as cars, SUVs, appliances and electronics.

Automakers were the worst hit with manufacturers such as Maruti Suzuki, Tata Motors, Mahindra & Mahindra, Hyundai reporting a drop in sales.

Tata Motors had said that they are looking at a waiting period of 6 months for electric cars and as low as 2 months for most other vehicles.

Apple CEO Tim Cook also warned that the shortage would affect production of iPhones and iPads. In addition, smaller phone makers were also affected.

Game consoles like PlayStation 5 and Xbox Series X are also in short supply.

India is a major importer

India has been a major importer as it imports almost all semiconductors to meet the demand, which is projected to reach around $24 billion to $100 billion by 2025.

Previous attempts to get companies to invest in the semiconductor space have failed, particularly as sophisticated manufacturing processes require huge investments, in addition to uninterrupted clean water and electricity supplies.

While India is seen as strong in the field of chip design, it failed to achieve the much-hyped fab manufacturing in the country, involving investments of between $5 billion and $10 billion.

However, the strategy of many global companies to exit the pandemic and look at ‘China Plus 1’ policy for procurement in early 2020 is likely to help in getting investments in India.

what caused the decrease

The Covid-induced lockdown was one of the major reasons for the shortage as it prompted factories to opt for temporary shutdown.

As plants reopened, electronic goods producers continued to place orders – creating an ever-increasing backlog for chips that can be as long as a millimeter.

However, it is not the only factor. Last August, the US banned foreign companies whose chips use American technology from selling to Chinese tech giant Huawei on espionage charges.

Huawei began stockpiling semiconductors before the restrictions took effect, and other companies followed their lead, further straining supply.

(with inputs from agencies)

FacebookTwitterLinkedinE-mail

,