The findings point to “disrespect towards the lives of workers and the conditions in which they work”. Describing the automobile giants as “role models”, it says they must demand very high standards and “respect” for human safety in their supply chain.

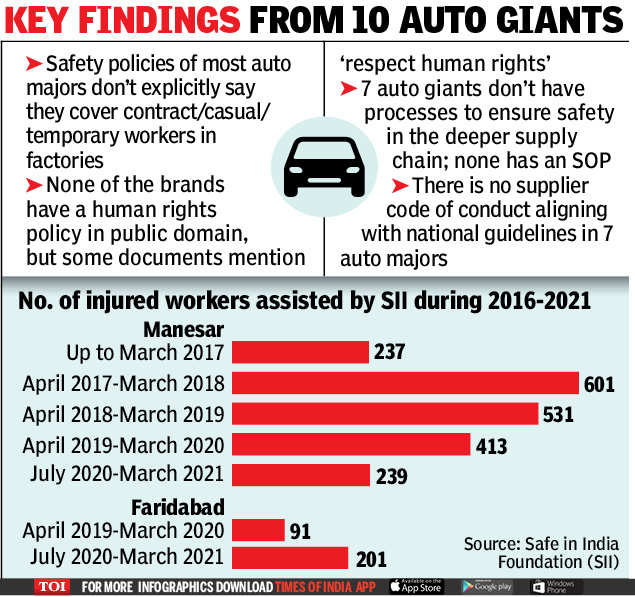

According to the report, the SII team has assisted over 2,600 injured workers since 2016-21 – 440 of these in 2020-21, a year of reduced manufacturing activity due to the pandemic – in the Gurgaon-Manesar and Faridabad automobile manufacturing sectors . . It says that about 70% of them have also lost their fingers or hands in factory accidents, leading to permanent disability.

The report states, “More than 90% of workers in the auto sector who assisted report that they were injured in factories supplying to one or more of the sector’s three largest OEMs (original equipment manufacturers). ”

The SII report is the result of its analysis of research into factory accidents and policies and practices of India’s largest OEMs or auto giants. Among its key comments on the policy framework is that most auto majors’ safety policies do not explicitly state that they cover contract/casual/temporary workers in their own factories and that seven out of 10 companies have supplier ethics. There is no code. To align with the National Guidelines for Responsible Business Conduct (NGRBC).

According to the report, about 90% of the injured workers who assisted and analyzed SII were migrants, who were from UP, Bihar and Odisha. 65% of them were contract workers and 95% were not affiliated with any union that could fight for their rights. Furthermore, the report finds that 59% of accidents occur on one type of machine – the power press.

Society of Indian Automobile Manufacturers (SIAM) acknowledged the problem and said the industry should come together to ensure safe working conditions for workers, borrowing from the best practices of automobile giants like Maruti, Tata and Bajaj. “Protecting workers is good for business, good for productivity. There have been some good practices, but there should be a lot more. These are some of the areas we found it important to focus our engagement with member OEMs: safety The focus is on how to share best practices, how to engage with all levels of the supply chain, and the issue of supplier code of conduct. Rajesh Menon, Director General of SIAM.

Vini Mehta, Director General, Automotive Component Manufacturers Association of India (ACMA), said, “The pandemic has brought the importance of human resource to the forefront for an organization – you need to take care of the employees as they work towards business continuity and productivity. are important for. ”

.